Easy handling and totally modular

The KINGFORM shuttering system is the ideal, cost-effective solution for the stationary production of a wide range of walls, floors and other precast elements. Due to the modular design, an extremely large number of possible combinations are possible at low investment costs.

Windows, doors and built-in parts are easy to position. Short set-up times and a particularly ergonomic working are guaranteed by the low dead weight of the individual components. You are completely flexible, no matter whether you want to work with steel or wooden covering.

Areas of application

Solid, sandwich or façade elements as well as precast columns and beams can be produced universally and cost-effectively with the KINGFORM shuttering system. For this purpose, the individual components of the modular system are flexibly combined on stationary tilting and casting tables, circulating pallets and long-line beds. A wide variety of external and internal contours as well as different wall dimensions and thicknesses can be realized in this way with the shortest possible set-up times.

Features

Due to high modularity an extremely large number of combinations are possible at very low investment costs:

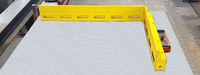

- Longitudinal or transverse shutters for all precast concrete elements with heights from 100 - 300 mm

- Concreteable on both sides, extendable in height, covering with steel or wood, manual handling

- High modularity, all components quickly and easily fixed

- Standard lengths expandable in steps of 500 mm, heights extremely flexible due to assembly

Advantages

From a simple combination of magnetic boxes, base shutters, attachments and corner connectors, precast concrete elements can be produced stationary and without a high degree of automation. All assembly processes are carried out manually and without a hall crane. Due to the high stability and form stability, bending due to improper handling is avoided. Holes on the rear side allow the assembly of additional installation parts. By means of the magnet technology the shutters can be easily moved and fixed at the desired element position. Since no screws are used between the magnet and the shutter, fast and precise work is possible.